I recently had the opportunity to review the newest hardware and features of the ABB Freelance control system and it is an impressive Micro DCS product. The ABB Freelance control system meets the needs of small to midrange process applications where a large DCS is not required. The Freelance system has its roots on the original Hartmann & Braun Freelance product, but with significant ABB investments to improve the system. ABB is committed to continuously improving and enhancing Freelance to meet user's changing needs.

Engineers evaluating possible solutions for small to midrange applications will do well to consider the Freelance system. The Freelance system combines easy engineering with open system architecture. ABB describes Freelance as a small footprint DCS for small to medium sized plants in the process industry and for applications requiring DCS functionality in a compact system with intuitive and efficient engineering tools.

Freelance is scalable from small to large system (click images below to enlarge them).

Freelance system enhancements have embraced open architecture with a fieldbus centered architecture supporting PROFIBUS PA, PROFIBUS DP, HART, and Foundation Field bus. Using the AC800 controllers systems can be configured for full redundancy.

IEC 61131-3 Programming

Freelance conforms to the IEC 61131-3 programming standard for controls programming. An integrated systems approach is used to configure control and process automaton using a large library of over 200 predefined functions to save engineering time and improve quality. ABB indicates that the Freelance 800F controller is proven in more than 14,000 applications.

Field Display Panels

The ABB Panel 800 family of displays provides options to meet a wide range of operator interface requirements. There are 5 touch panel displays ranging from 4 to 15 inch displays and 4 function key panel displays with screens up to 10 inches.

Software Features

Control Builder F engineering software is used to configure the systems and the DigiVis operator console software is used for HMI. Key software features include:

Integrated Alarm and Message Handling

Readymade Faceplates per Tag

Integrated Configuration – Database

Cross References

Extended SFC-Control (Start, Resume, Monitor, Wait, …)

Trending, Historian and Archiving

Redundancy Option

Integrated Control System Diagnostics

System Level Diagnostics

Easy Configuration, 3D Libraries & Pre-defined Displays

Trend/Archive Analog and Digital Process Variables

Historian

FDT Support

Freelance now has built-in Fieldbus management using the FDT standard for HART, PROFIBUS, and Foundation Fieldbus. These capabilities are built into the systems engineering tool for online and offline configuration, calibration, and parameter access.

OPC Interface

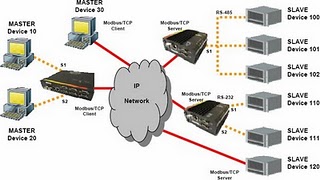

Freelance has servers for open connectivity with OPC DA (Data Access) and OPC AE (Alarm & Events).

AC 700

The AC 700 is the newest field hardware that is based on ABB’s proven AC 500 hardware platform. The AC 700 has I/O modules with detachable terminal units and can support up to 8 I/O modules. The AC 700 processor is a Motorola Power PC and can be configured with up to 2 MB Battery-backed SRAM, 8 MB SDRAM and 4 MB FLASH memory. The unit has a local display for control and diagnostics, 1 Ethernet Port, and two RS-232/485 ports. The initial I/O modules available support:

Digital Inputs: 24 volt DC

Digital Outputs: 24 volt DC

Analog Inputs: Milliamp, Voltage, and RTD

Analog Outputs: Milliamp and Voltage

Application Engineering Advantages

Single database for all controllers

Quickstart Computer Based Training on DVD

S88 batch control only requires user to configure it for applications

Diagnostics in DigiVis Monitor Field Equipment Health

OPC Interface

IEC 61131-3 Language Standard

Control Builder supports FDT simplifying engineering and commissioning

Time synchronization of nodes with master

Pre-engineered displays

SOE option card for rack based I/O with 2millisecond resolution

Redundancy Options